Suzhou GINFON Logistics System Co., Ltd. (referred to as "Suzhou GINFON") is a system integrator focusing on logistics sorting, warehousing and intelligent factory automation. It has independently developed various intelligent, efficient and flexible sorting systems and warehousing automation systems, and has formed a rich series of products and solutions of logistics sorting and warehousing equipment, providing high quality services for many customers at home and abroad. Nowadays, logistics sorting technology continues to progress, is developing to the direction of intelligence and flexibility. As a large enterprise in this field, how does GINFON Company view this trend of technological development? What kind of layout does it have in this direction? Recently, our reporter had the honor to interview Mr. Liu Hongfeng, chief engineer and director of R&D center of the company, and asked him to share Jin Feng's exploration on intelligent flexible sorting of logistics.

Liu Hongfeng, chief engineer and R&D director of GINFON, holds a master's degree from Osaka University. He has many years of experience in software, Internet of things and logistics automation industry in Japan and China, and then served as R&D center director and chief engineer of GINFON

Reporter: As the leader responsible for technology research and development of GINFON, how do you view the development of logistics transportation and sorting technology?

Liu Hongfeng: First of all, we serve our customers as a provider of logistics technology and systems engineering solutions. The fundamental driving force to promote the development of logistics technology is the change of market demand. Founder of the Golden Peak Company andCEO Take the development of our company as an example. In the early stage, GINFON Company mainly served customers in the e-commerce and express industry. Due to the blowout development of e-commerce and express delivery, the intelligent development of logistics system in the industry is promoted. The demand for automatic sorting system of logistics is greatly increased in large distribution centers. In the development process of the e-commerce express industry, logistics automation equipment has solved many problems of customers, such as the rapid growth of business packages, especially in the past few years when the e-commerce industry was greatly promoted, express distribution centers and outlets often appeared the phenomenon of warehouse shortage. With the continuous construction of logistics automation equipment in recent years, the large-scale popularization and application of automated transportation and sorting equipment in the industry, we have rarely seen the phenomenon of warehouse bursting.

However, we should also objectively recognize that for e-commerce and express delivery enterprises, there is still room for continuous optimization of the existing solutions. For example, the cross belt sorting machine system, which is widely used in the express industry, currently relies on manual operation in the link of package supply and package collection: a set of standard cross belt equipment is generally available12A supply port, yes12Name the package operator; At the set packet interface, it is usually required10~20Nameset package operator. There are artificial participation in the link, there must be artificial rules of operation. However, there are also moments of operator error and fatigue, which will increase the probability of equipment sorting errors and affect customer service experience. In addition, with the continuous rise of labor costs, especially during the promotion period of e-commerce and the impact of the epidemic in recent years, the shortage of manpower, e-commerce and express customers also have a strong demand for replacing manpower with equipment to continuously improve the automation rate. Therefore, in the process of further automation of the system, how to replace and reduce labor in the corresponding links is the logistics technology and solution provider to consider and solve.

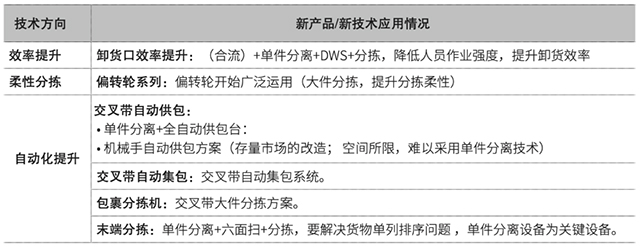

Double - layer cross - belt sorter system developed by GINFON

For e-commerce and express delivery enterprises, their demand for equipment stability is in the first place. Secondly, they are also very concerned about the cost of equipment, because the cost of single express ticket is decreasing year by year, and they are facing great operational pressure. When this pressure is extended to the construction of logistics systems and equipment procurement, it is often reflected in the continuous improvement of equipment operation efficiency requirements. Through the improvement of space utilization rate of multi-layer equipment, the comprehensive energy consumption of equipment and energy saving schemes are also very concerned.

In addition, the business expansion of express delivery and express delivery enterprises also creates new demands for the selection of equipment and solutions, such as the transformation and upgrading of express delivery industry in recent years, and the integrated development of express delivery and express transportation. However, in terms of logistics operations, express and express business of many enterprises are still two sets of independent operation systems, which not only makes the operation cost high, but also fails to improve the efficiency of the express industry based on manual operation. Therefore, the integration of automatic delivery and sorting of large items and oversized overweight irregular parts of the need to increase.

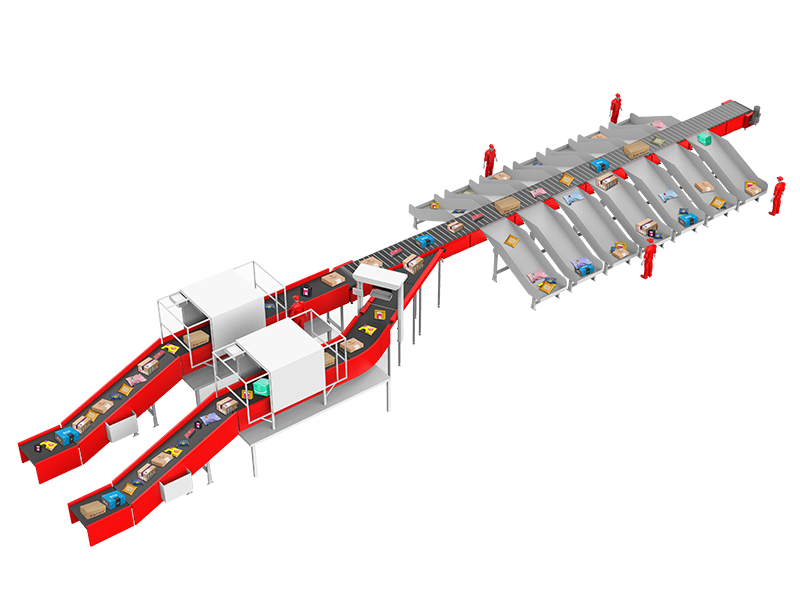

From the perspective of industrial technology development, transportation and sorting industry itself is a technology application industry. In recent years, the development of emerging technologies such as the Internet of Things, big data, cloud computing and artificial intelligence has greatly accelerated the development of logistics technology and product system towards the direction of intelligence, automation and flexibility. For example, the improvement of the utilization rate of electronic sheet and the progress of visual identification technology have promoted the generation of intelligent and flexible sorting technology and solutions. The manufacturers in the industry have developed the single piece separation system of express package high-speed single row sorting, the flexible sorting technology equipment of large balance wheel, and the automatic package supply of cross belt/Set package system, end sorting system (single piece separation+Six-sided scan+Sorting) and other new technology and equipment innovation and application. The new conveying and sorting system has higher and stronger operating efficiency, accuracy, stability, flexible sorting and other capabilities, which further promotes the release and development of market demand and makes the development of the industry enter a virtuous cycle.

GINFON storage and production workshop

Reporter: Logistics transportation and sorting technology toward intelligent and flexible direction, reflected in the specific aspects?

Liu Hongfeng: First of all, recently3DThe rapid development of detection technology represented by vision and rapid cost reduction have become one of the important factors to promote the flexible development of transportation and sorting. The location information, volume information and other spatial information of the goods being transported and sorted can be judged by visual identification. In addition, big data andAITechnology identifies a wide variety of goods. By using the spatial information of goods, the running track of goods sorting can be optimized and controlled according to the length, width, height, center of gravity and other parameters of goods, so as to reduce the acceleration and angular acceleration of goods sorting, prevent the dumping of goods in operation, avoid the wrong division or damage of the sorted goods, and realize flexible sorting. With the recognition of goods shape, different control algorithms can be used to improve the sorting effect according to whether the goods are rigid cardboard boxes or soft package goods that may produce deformation. Such technology is very useful in the sorting of large pieces.

Secondly, through real-time monitoring of the running state of automated conveying and sorting equipment and cargo throughput of each link, combined with the personnel layout and human efficiency monitoring of the business operation system, man-machine cooperation can be optimized and improved to enhance the comprehensive efficiency of the system. During the operation of the equipment, if the operation load is unbalanced or overloaded, the system can give an alarm to the field manager or operator and adjust the personnel arrangement accordingly, so as to ensure the smooth and efficient working state of the whole system and realize the flexibility of the system.

In addition, logistics automation system is an ecosystem of the Internet of Things. Through the Internet of Things technology, cloud technology, big data andAIThe comprehensive application of technology can enable the system to realize real-time monitoring and diagnosis of the health status of logistics equipment and early warning of possible faults of equipment. Operation and maintenance personnel can carry out targeted maintenance and prevention, improve the efficiency of operation and maintenance personnel, and reduce the adverse impact of equipment failure and shutdown on production. This is also a hot topic in the development of logistics intelligent sorting system technology.

Reporter: What technical breakthroughs and explorations does GINFON have in intelligent flexible sorting technology? What kind of value can it bring to the customer?

Liu Hongfeng: We mentioned earlier that the distribution center of express logistics still needs manpower. However, with the development of vision and robotics technology, and the continuous reduction of costs, the further automation of related processes is moving forward. For example, the cross belt automatic package supply is currently manually taken from the package supply chute or the package delivery loop to the semi-automatic package supply table. Goods are stacked in both the baling chute and the baling loop. In order to solve the automatic delivery, it is necessary to realize the automatic extraction process from stacked goods to discrete goods. There are two solutions: one is based on3DVisual single piece separation system to achieve cargo from3Dimension stack to2Dimensionality reduction of the dimension plane and further implementation from2Dimension side by side1D single column sorting function, and then docking automatic package platform to achieve no automatic supply. The other solution is to solve the problem of package stacking by manipulator. Through visual recognition, the manipulator grabs a single piece of goods and stably places them on the package supply table to realize unmanned automatic supply. Due to the complexity of the package form and material, the grasp accuracy and comprehensive efficiency of the manipulator are still being further improved. With the continuous advancement of the exploration of these technologies and the continuous reduction of equipment costs, relevant solutions have entered the practical application stage.

Compared with other industries, a particular difficulty in the automation of express delivery industry is the complexity of packages. Some other industries logistics automation operation object is the external packaging is more standardized and unified, and the express industry automation system to face the goods may be packaging shape, size, material is very complicated, which brings great difficulties to the operation of automation equipment. Sorting operation should consider the accurate division, but also to avoid the damage to the sorting goods, to achieve flexible sorting. In the past few years, when GINFON launched the large-sized intelligent swing arm system, the idea has been to "push" the goods down, rather than "hit" down. Whether it is through the front edge machine to improve the running track of goods, or through the visual detection device to judge the position of goods, the system can control and reduce the relative speed of the swing arm and goods contact, reduce the impact, gently push the goods out, reduce the damage to the sorting goods. Recently, in the launch of large intelligent deflection wheel system, through the use of3DVisual detection technology to obtain three-dimensional spatial information of goods, as well as weight information through weighing, combined with the identification of the shape and type of goods, the system uses different control algorithms to optimize the sorting control details and achieve flexible sorting. These technical applications fully embody our pursuit of intelligent flexible sorting concept.

Also, GINFON has developed the GINFON Cloud service platform, through IOT - PLC - SCADA - CLOUD - BigData - Mobile Data link, construction of equipment operation status monitoring, intelligent data analysis and early warning system; To provide customers with real-time monitoring, early warning Settings, overall adjustment functions and services. GINFON Cloud system can monitor and display the running status of sorting equipment in various sites in real time, realize remote monitoring and maintenance guidance, and carry out the whole life cycle management of equipment.

Reporter: Would you please introduce the idea of technology research and development of GINFON Company, the process of research and development and the achievements.

Liu Hongfeng: GINFON is positioned as a system integrator based on core products. Therefore, in addition to the ability of system planning and integration, the competitiveness of core products is also the basic guarantee for the long-term development of the company. Since its inception, the company has invested a lot of resources in technical product research and development. From the domestic substitution in the early stage to the "customized optimization" in line with the needs of the rapidly developing domestic industry, GINFON has always stood in the perspective of customers, in line with the concept of helping customers to continuously reduce costs and increase efficiency, and create value for customers, to provide products and solutions that can help customers solve practical problems.

GINFON Test Research and Development Center

The product research and development process of GINFON is mainly divided into five stages: product planning, product planning, product design, prototype proofing test and field test. In the whole process, we collected and analyzed market and customer needs from multiple dimensions to determine the direction of product development. Then, we will set the goal of product research and development and determine the key indicators and specifications according to customer needs and technology development status. In product design, various schemes will be fully demonstrated and the optimal design scheme will be formulated. Then, through full testing and optimization of the prototype, the product is iterated and shaped. Finally, the processing completeness of the system under complex conditions and various abnormal conditions will be tested in real production scenarios.

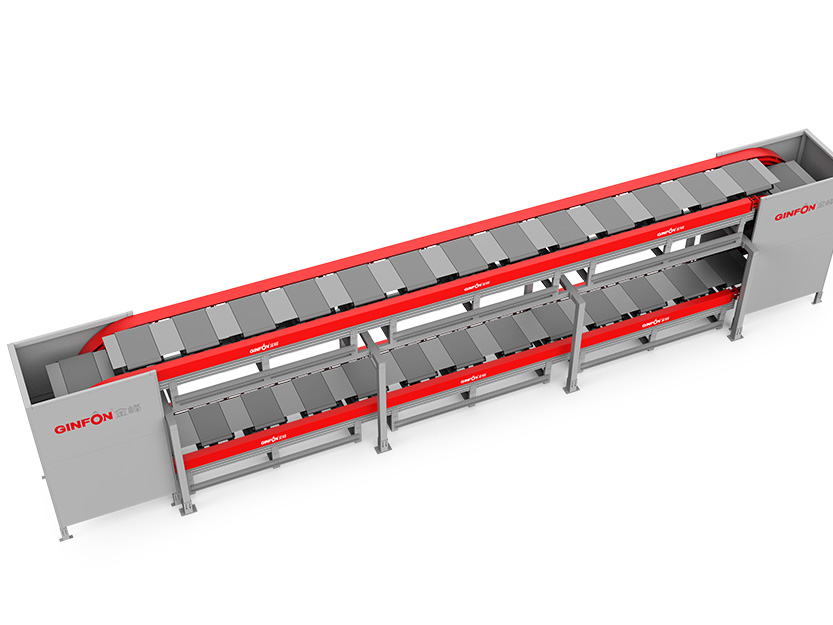

The research and development direction of GINFON technology and the application of new technology

After that, it enters the stage of mass production. We will carry out strict quality control in product production and site installation and commissioning. In the future, we will continue to optimize and regularly upgrade products for further problems found in customers' use.

The dynamic automatic weighing, scanning and volume measuring machine developed by Jin Feng

In the past few years, our focus has been to provide automated logistics solutions for large distribution centers. in2015We introduced the swing arm sorting system in 2000;2016The cross-belt sorting system was introduced in 2005.2017In 2005, we started to make serialized products for the cross-belt sorting system, and launched the double-layer cross-belt system. In the same year, we also launched the deflection wheel series products.2018Annual launch4Layer cross belt system and double row cross belt system; We also launched the automatic weighing and scanning code all-in-one machine, used together with the large parts sorting system;2019Launched the double-layer straight cross belt products and mechanical single-piece separation system;2020In 2005, the company launched linear turntable machine, visual separation system and automatic package solutions for manipulator. This year, the main direction of our research and development and technology is to solve the problem of speeding up the unloading port, improve the unloading efficiency, so as to make full use of the production capacity of the main line and the efficiency of the balance wheel. In terms of the improvement of the cross-belt sorting system, we are also doing research and development in the aspects of fully automated baling supply and automated baling collection.

GINFON It is a comprehensive solution provider and key core product manufacturer focusing on logistics automation business in intelligent logistics and intelligent manufacturing. Based in Suzhou, the company has R&D teams and technical consultants in Japan, Europe and the United States. GINFON has independently developed a full series of intelligent, efficient and flexible sorting systems and warehousing automation systems, and has formed a complete series of sorting and warehousing products, to provide customers at home and abroad with intelligent logistics automation system engineering solutions, and to provide the whole process of project management implementation, management and other comprehensive services. Welcome to inquire, you can also consult online/Leave a message and communicate directly with customer service.

GINFON GF-CBS series cross-belt sorter system has the advantages of high efficiency, accuracy, flexibility and high utilization rate as a type of sorter solution with both economy and reliability. It can sort various kinds of goods weighing from 10g to35 kg, especially suitable for postal express, e-commerce and distribution centers (medicine, food, tobacco, cosmetics and clothes, etc.).

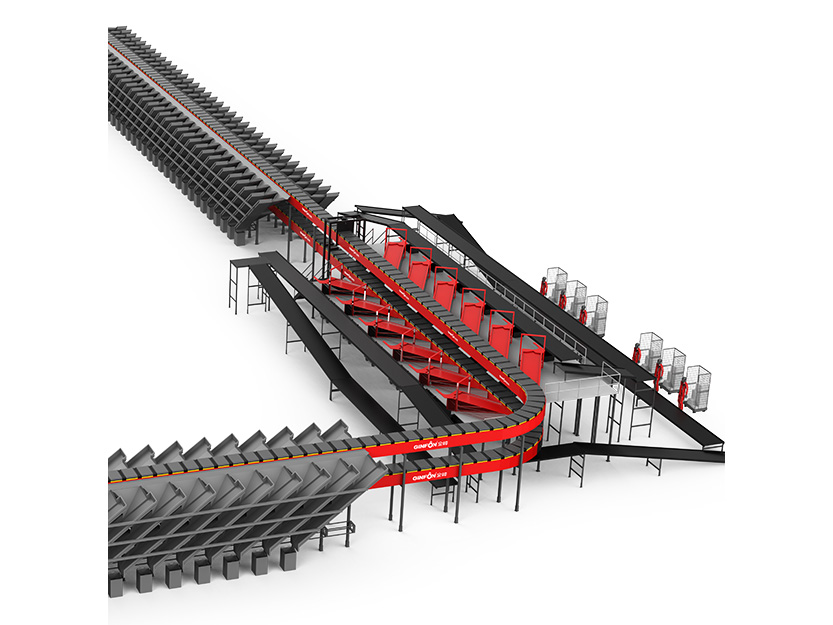

The system is a new type of high-speed sorting equipment and an upgraded version of the traditional horizontal circular conveying mechanism. The equipment consists of two circulating conveying mechanisms, the upper and lower, and a sorting trolley carryingasmall belt conveyor, which uses dual software and hardware responses to achieve fault warning and spare parts management.

The linear narrow-belt sorter system is mainly used in the e-commerce and express industry. It is an ultra-efficient linear sorting equipment that can solve various types of parcels, and has the advantages of high efficiency, precision, flexibility, intelligentand high space utilization rate. Shape of sorted items:Soft parcel, flat piece, sack, carton, abnormal parcel with stable center of gravity.