Intelligent logistics refers to the full application of artificial intelligence in each link of logistics and intelligent integration of product system with independent technology to achieve a balance between efficiency and cost. In order to achieve theend-to-end full life cycle project management ability and large integrated project delivery guarantee ability, the following GINFONtakes you to understand the logistics personnel must know the four advantages of intelligent logistics system.

Details >

Recently, Suzhou GINFON Logistics Equipment Co., LTD. (referred to as "GINFON Group") has successfully completed a D round of financing of more than 200 million yuan. This round of financing is jointly led by Shenzhen Qianhai Mother Fund and Shanghai Daohe Capital. The original shareholder Jiangsu Yida participated in the second round of follow-investment. The main purpose of this round of financing is to increase the investment in product research and development, strengthen the construction of high-quality talent team, expand overseas business, and improve the company's comprehensive service ability and technological innovation ability at home and abroad.

Details >

SuzhouGINFONLogisticsSystemCo.,Ltd.(referred to as "Suzhou GINFON") is a system integrator focusing on logistics sorting, warehousing and intelligent factory automation. It has independently developed various intelligent,efficient and flexible sorting systems and warehousing automation systems, and has formed a rich series of products and solutions of logistics sorting and warehousing equipment. For many customers at home and abroad to provide high quality service.

Details >

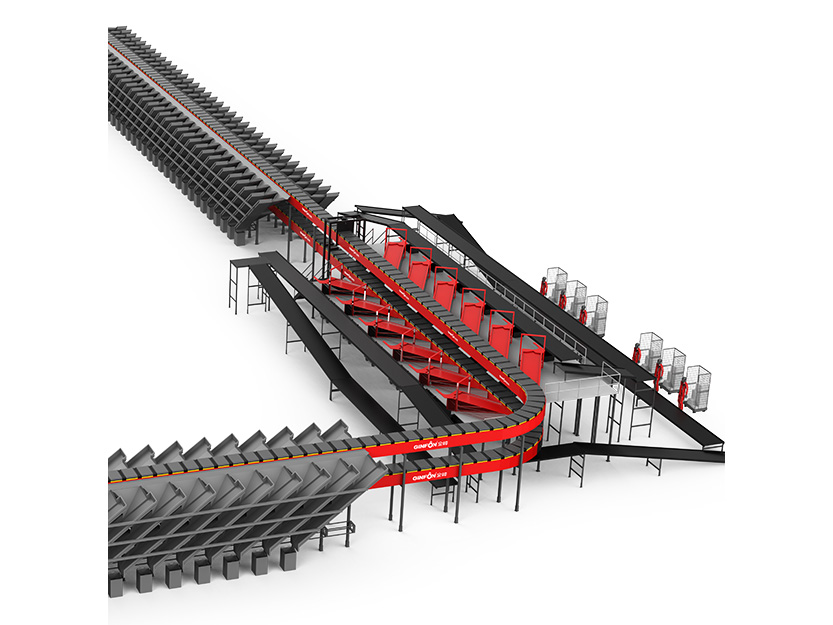

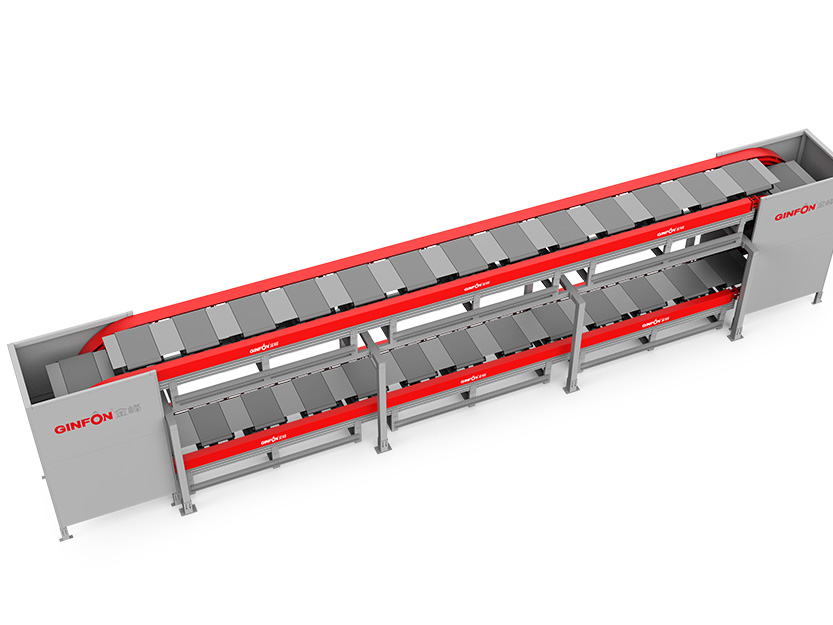

GINFON GF-CBS series cross-belt sorter system has the advantages of high efficiency, accuracy, flexibility and high utilization rate as a type of sorter solution with both economy and reliability. It can sort various kinds of goods weighing from 10g to35 kg, especially suitable for postal express, e-commerce and distribution centers (medicine, food, tobacco, cosmetics and clothes, etc.).

The system is a new type of high-speed sorting equipment and an upgraded version of the traditional horizontal circular conveying mechanism. The equipment consists of two circulating conveying mechanisms, the upper and lower, and a sorting trolley carryingasmall belt conveyor, which uses dual software and hardware responses to achieve fault warning and spare parts management.

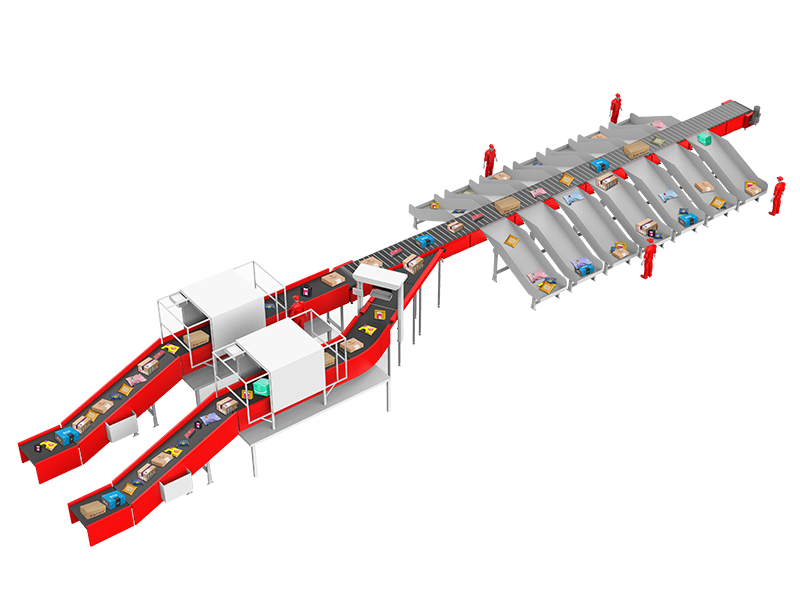

The linear narrow-belt sorter system is mainly used in the e-commerce and express industry. It is an ultra-efficient linear sorting equipment that can solve various types of parcels, and has the advantages of high efficiency, precision, flexibility, intelligentand high space utilization rate. Shape of sorted items:Soft parcel, flat piece, sack, carton, abnormal parcel with stable center of gravity.