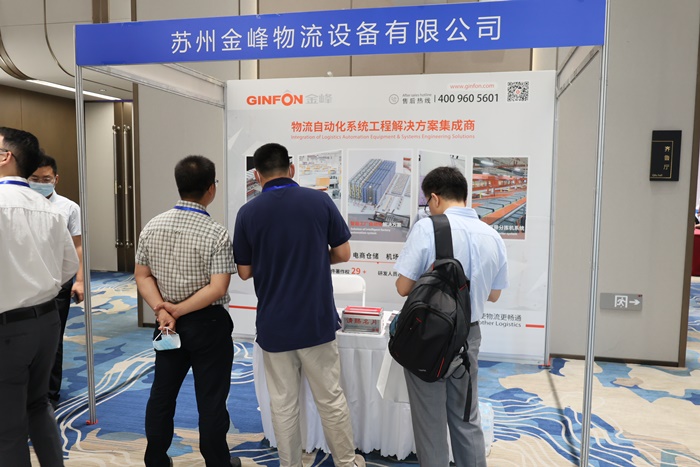

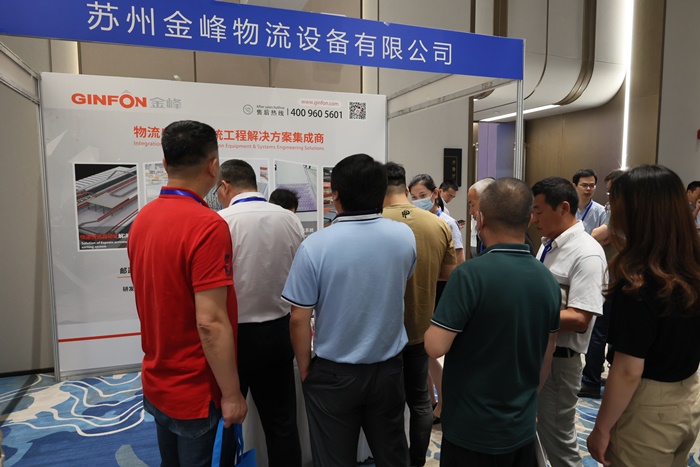

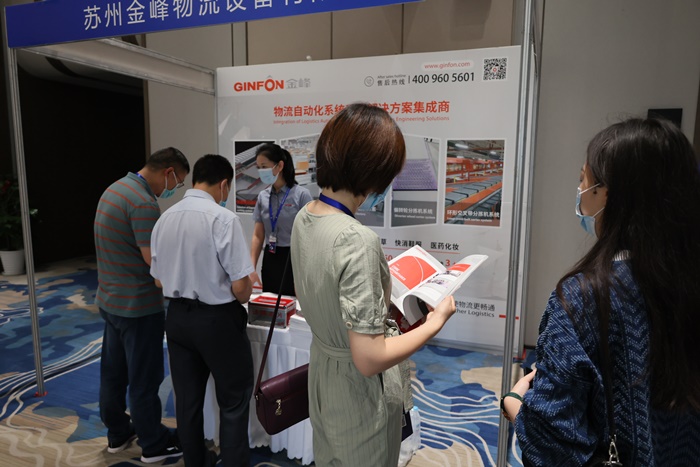

In order to implement the spirit of the Fifth Plenary Session of the 19th Central Committee of the Communist Party of China, with the goal of building a modern circulation system and basically realizing the modernization of the warehousing industry, promote the sharing and greening of warehousing facilities, the standardization and digitalization of the logistics industry and the development of the networked integrated platform of the logistics system, and open a good bureau for the modernization of the 14th Five-Year warehousing industry. Organized by China Warehousing and Distribution Association, the 16th China Warehousing and Distribution Conference and the 8th China (International) Green Warehousing and Distribution Conference was held in2021years6month23day-25It was successfully held in Jinan, Shandong Province. For this meeting, GINFON As a logistics automation system engineering solution integrator was invited to attend the conference, and brought logistics automation intelligent warehouse allocation and sorting system solutions.

Based on sorting, enabling warehouse allocation

In recent years, the transaction volume of e-commerce and the revenue of express business have increased year by year, and the demand for intelligent warehousing and sorting has become an important growth engine for the logistics industry. How to help the warehousing industry reduce labor costs and highlight the advantages of intelligent warehousing? GINFON adopts modern Internet of Things information technology and logistics automation integration experience to develop intelligent logistics warehousing management system in line with the development of modern enterprises, and uses big data, cloud computing,AITechnology and other technologies can improve the utilization rate of storage space to a greater extent, reduce storage costs, improve operation efficiency, and contribute to the realization of the national "carbon peak, carbon neutral".

GINFON has been committed to the field of automatic sorting for a long time, and has undertaken hundreds of large-scale logistics distribution center projects. With the demand for automation and intelligent solutions in the warehousing industry, GINFON has set up intelligent factory Business Division, which focuses on providing automated solutions for warehousing and distribution, and offers suggestions for promoting the green and intelligent development of warehousing and distribution industry.

Ingenuity, quality engineering

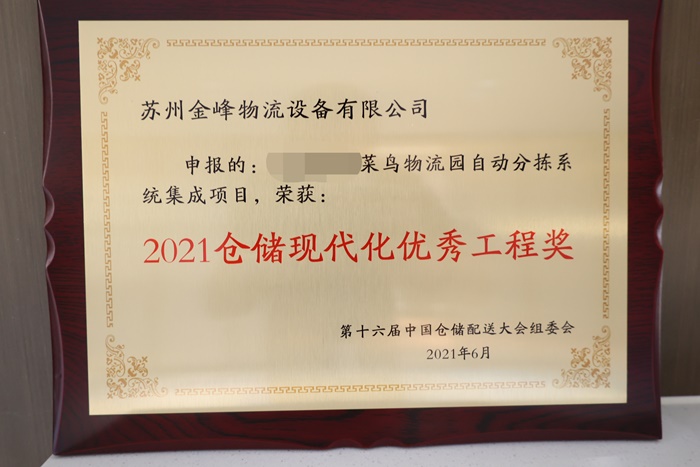

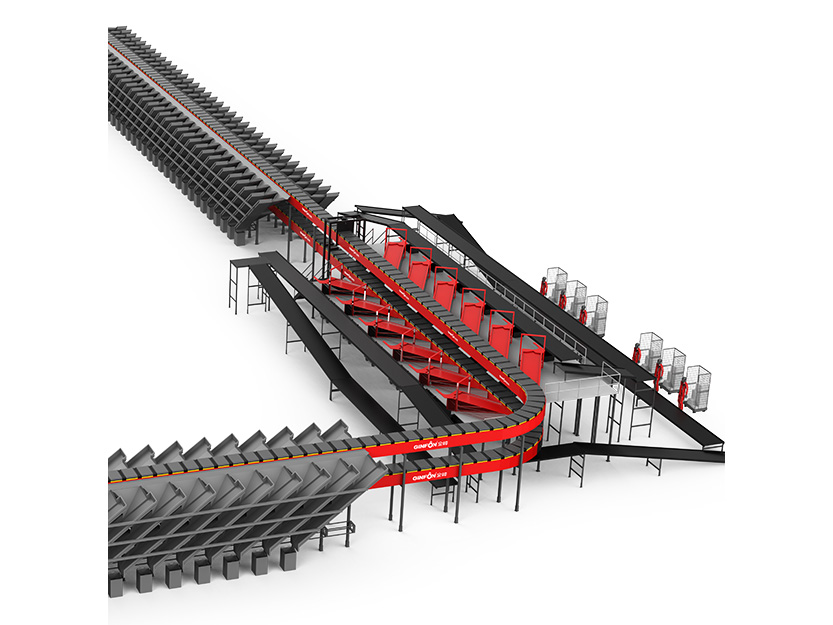

The integrated project of automatic sorting system of a large logistics park created by GINFON has large engineering quantity, short construction period, limited space and greater flat efficiency. This project adopts the patented products invented by GINFON-Single-row double-layer cross-belt sorter system and double-matrix layout, with double-layer chute, saving space, higher sorting efficiency. The successful implementation and operation of the project solved the problems of manpower shortage of customers and high cost of enterprises, and was highly recognized by customers in speed, quality and efficiency, and promoted the rapid development of customers to the direction of automation, intelligence and information.

Technological innovation leads the wind

6month25The keynote speech of "Review and Prospect of automated Sorting Technology in Express and Express Industry" was delivered at the forum in Japan, from the overview of express and express industry development, review of automated sorting technology development and innovation of automated sorting technology&It also introduces the innovation cases of enabling enterprises, and discusses the future development opportunities of warehousing and distribution supporting technologies with the leaders of various enterprises.

The future,GINFON We will continue to uphold the spirit of craftsman and make continuous efforts to deepen the field of warehouse automation and automatic sorting, deepen research and development in various industries, improve the quality of service, and cooperate with ecological partners to provide logistics automation system solutions more in line with the needs of customers.

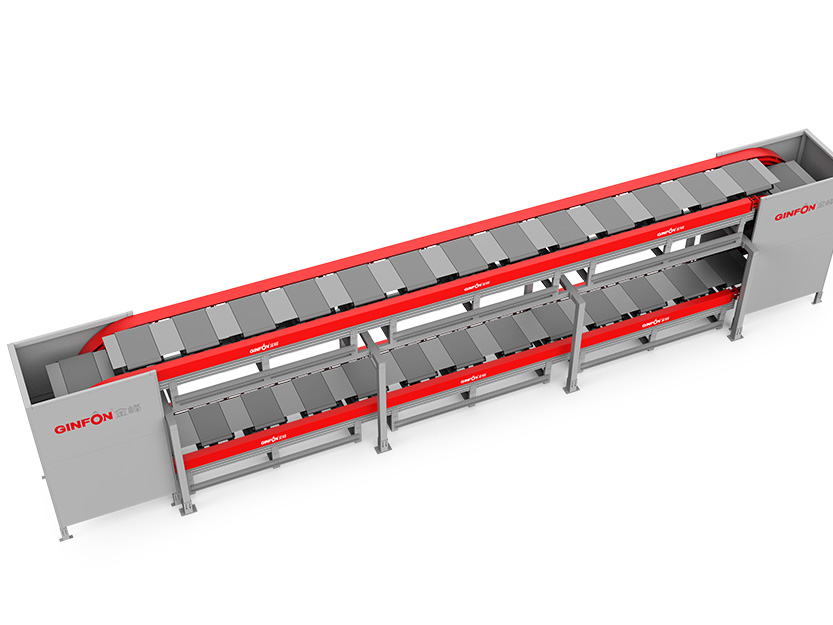

GINFON GF-CBS series cross-belt sorter system has the advantages of high efficiency, accuracy, flexibility and high utilization rate as a type of sorter solution with both economy and reliability. It can sort various kinds of goods weighing from 10g to35 kg, especially suitable for postal express, e-commerce and distribution centers (medicine, food, tobacco, cosmetics and clothes, etc.).

The system is a new type of high-speed sorting equipment and an upgraded version of the traditional horizontal circular conveying mechanism. The equipment consists of two circulating conveying mechanisms, the upper and lower, and a sorting trolley carryingasmall belt conveyor, which uses dual software and hardware responses to achieve fault warning and spare parts management.

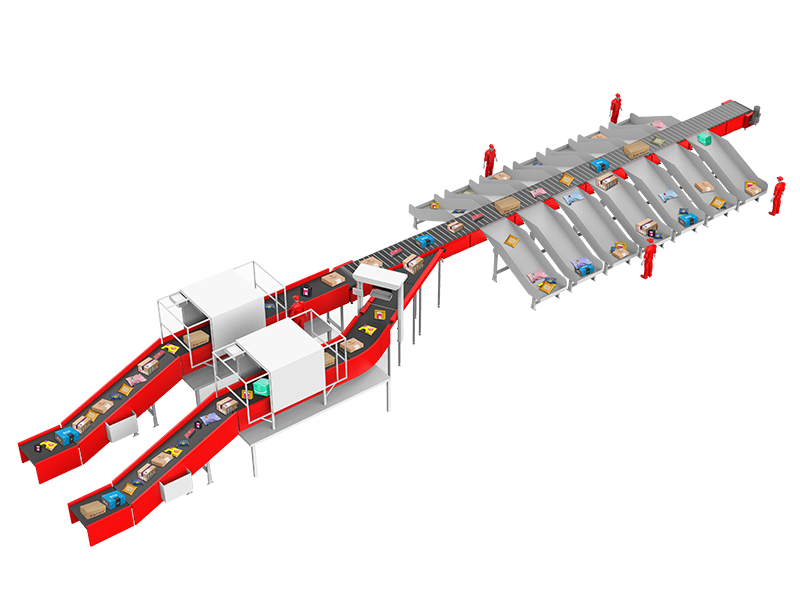

The linear narrow-belt sorter system is mainly used in the e-commerce and express industry. It is an ultra-efficient linear sorting equipment that can solve various types of parcels, and has the advantages of high efficiency, precision, flexibility, intelligentand high space utilization rate. Shape of sorted items:Soft parcel, flat piece, sack, carton, abnormal parcel with stable center of gravity.