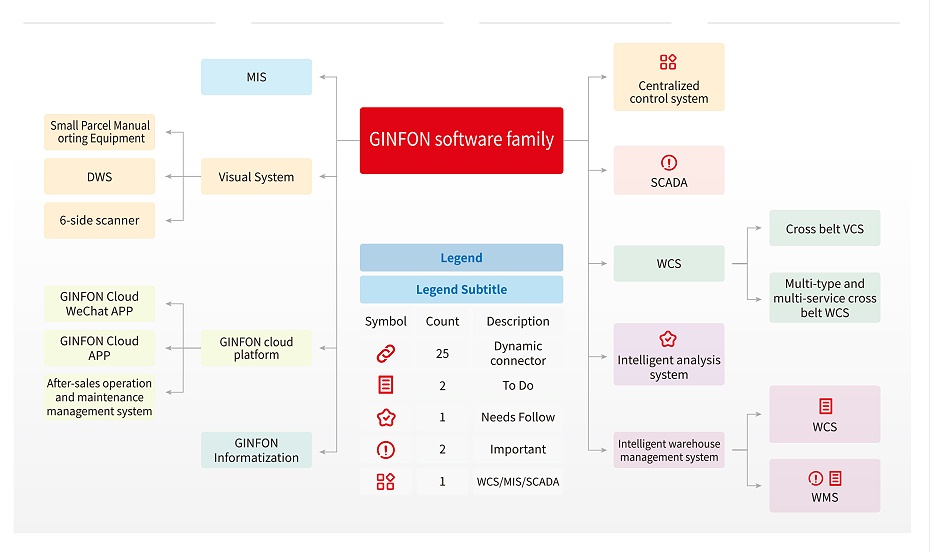

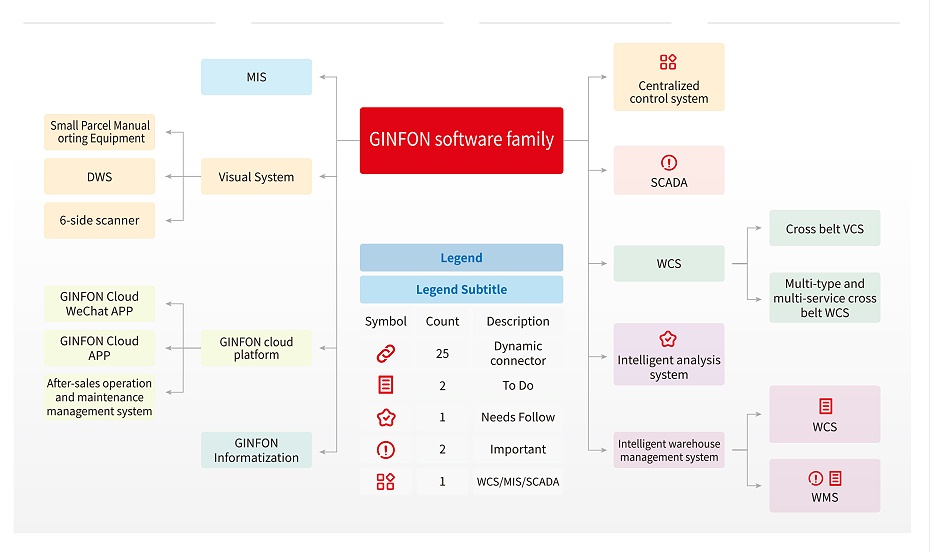

Intelligent informatization · GINFON cloud platform

GINFON cloud platform independently developed by GINFON Group defines hardware via software, and builds the system of equipment operating status monitoring,

intelligent data analysis and early warning through the logistics control operation

platform and the intelligent management system as well

as the IOT - PLC - SCADA - CLOUD - BigData - Mobile data chain.

-

01Centralized management Solutiontime and labor waste for maintenance in case of distribution of the equipment at various sites

-

02Data collection Solutionoverdue learning of equipment operation situation

-

03Budget analysisSolutionkey data such as efficiency of productivity are difficult to obtain

-

04Remote maintenance Solution equipment maintenance plan is not justified

-

05Centralized monitoring Solutionafter-sales maintenance service response is delayed

Technical strength and advantages

GINFON IoT technology platform: based on intelligent data analysis, realize early warning of equipment operating status, and reduce accidental shutdown

by directional spot check on the equipment in advance so as to ensure production for customers

and greatly decrease system maintenance.

-

-

Technology R&D team GINFON bears perfect product R&D and technology application ability, personnel of the technology R&D team account for more than 50% of the whole staff, and all key technical personnel have over 15 years of practical experience in the industry; 3+ overseas R&D and consulting teams:

GINFON has three overseas R&D and consulting teams in Europe, the United States and Japan, convening intelligent logistics experts at home and abroad and introducing new technologies and new ideas in the industrial development.

-

-

Innovative product application Launch 2~3 new products every year and continuously conduct serialized extension and technological upgrade for existing products; GINFON has successfully applied for 244 R&D patents (25-30 patents applied each year). Put into operation in a large scale in the industries of e-commerce and express in 2015, and undertake whole site planning and automation construction of the distribution centers of headquarters of SF Express, Yunda, YTO Express and Shentong, with a high degree of market recognition.

-

-

System reliability guarantee One stop of systematic design, software development and project integration, the system operation stability can be improved through systematic design and a continuous optimization and iteration process; Continuously optimize HMI, strengthen the fool-proofing design and system abnormality detection function to effectively improve the operation reliability and effectiveness of intelligent logistics equipment.

Intelligent & informatization system software recommendation

The intelligent logistics system is an organic combination of “a hardware, a software and an Internet”, composed of intelligent hardware via the Internet of Perception. It is an intelligent system to realize automatic data flow

in a

wider scope and field for multiple small units, as well as to realize interconnectivity and interoperability of intelligent logistics hardware at multiple unit levels.

High availability GINFON cloud platform establishes a guarantee mechanism for node failure so as to ensure that the system can recover quickly from any failure and continue to provide services.

High availability GINFON cloud platform establishes a guarantee mechanism for node failure so as to ensure that the system can recover quickly from any failure and continue to provide services.

Load balance In a cloud computing platform, a high load on a node will affect performance of upper-layer application on such node, thus load balance can effectively improve resource utilization rate.

Load balance In a cloud computing platform, a high load on a node will affect performance of upper-layer application on such node, thus load balance can effectively improve resource utilization rate.